Quality Management Systems

Quality Management – Dissected

I’ve been bleating on in my last two posts regarding management systems. Yes, I have focussed on health and safety, primarily because it’s the one management system that appears to make sense to all concerned. Let’s face it, when we start talking quality management it seems to leave most people with either a Sunday morning taste in their mouth or a nosebleed.

The reason health and safety is easier to get over the line, in most cases, is due in part to the level of understanding we all have for it. Whether manager or employee, the idea of not getting hurt or becoming ill is pretty easy to comprehend. That, and there is usually some pretty robust and well-policed legislation sitting in the background waiting for us to mess it up.

Unfortunately, this is not so for quality.

I am sure you are all aware that the ISO 9001 standard was updated in 2015. Well, if you have a certificate, I am sure you are aware. If you don’t then I have probably just lost you as a reader and I wish you well on your travels…

If you’re still here, I’d like to pick up a few points regarding this standard. It’s had some bum press since its publication, but I think we should put that aside for the moment. I want to look at some areas I feel are rather interesting (I don’t get out much).

Rather than focus on its suitability for certification or how open to interpretation it is, let’s have a brief look at its core.

There are ten elements to the standard, the High Level Structure, developed by the genii in Geneva. The first three elements are there merely to weed out those who don’t have the determination to get to the good stuff,(introduction, preface, definitions, normative references – Yawn). Elements four to ten are where the real magic happens. These are what are lovingly termed as the “Requirements”. And in this case, these are applied to Quality…

Now I realise, that once you write good ideas into a document and call it a standard, your average human will switch off and go back to watching re-runs of Judge Judy, but let’s pretend this is not actually a standard for a moment. Let’s pretend, for a short while at least, that this is actually a bucket full of ideas. Forget about certificates, forget about external auditors and consultants, just for a second and let’s take this document on face value.

At its centre I have placed leadership…

This is imperative for a business to not only thrive, but survive. The idea in this bucket is that the leadership team (and I mean leaders at all levels) are on board and support the quality program. It’s just not left to some poor sod in the lab with the misfortune of having the title Quality Manager, who runs around like a Chihuahua on meth, wondering if they’ll still have a job on Wednesday. The only way we can engage leaders is by making this real to them.

Context of the organization…

Where does your business sit in the grand scheme of things? What factors influence your ability to provide products and services to your clients? Who are the participants in the game and how often do we take the pulse of what’s going on around us? Your systems should be inextricably linked to these factors and players, and should be able to roll with the punches. Failure to recognise these as a major influence on your business and its processes leads to, well…Failure.

Planning…

In a nutshell, this area is where it takes off. We take what we want to do, within the context of where we must do it, and develop how we are going to get there. Sounds simple yes? The problem is this; historically we have seen the planning of our systems and processes as separate to the what we are as a business. This is where the disjoint usually occurs, as it is when we give the project to the “Quality Person”. Now having been the Quality Person in a number of organization and for a number of years I know what I am talking about. The QP, whilst hard working, diligent and not unattractive, tends to be pretty low on the list when it comes to invites to the strategic planning meetings. After all, aren’t they the ones that want to stop the machines at the wrong time or spend extra money when you least expect it. Planning needs to be at the highest levels. Your business plan, your strategy, your big picture… Call it what you will, but it is your quality plan. This planning encompasses all areas.

If it affects business, it’s quality.

Support…

Once we have our plan, we need to resource it. So many organizations have come unstuck by identifying exceptional paths to greatness only to be hamstrung when the necessary support wasn’t forthcoming. Have we got the equipment, facilities and people to get the outputs we need? Have we got the knowledge base to help us through the delivery of the plan?

Operations…

I don’t need to tell you how to operate. It’s your business and you’ve been doing it for years. I wouldn’t be so arrogant as to tell you what you have been doing was wrong. You know your products and services, you know your people and limitations. What I want you to do, is start to look at things holistically. How can we take what we have discussed so far and apply it in a practical sense? Are your operations controlled? Or are you focussed on merely one aspect, the out-put for instance. I had one Managing Director, many years ago, who basically said, “I don’t care what you make, just make lots of it and I’ll sell it”. Hey, it’s a strategy… and it worked for a while, until returns started to trickle back. The ensuing witch hunt made Salem look like a game of Where’s Wally. Anyway, I digress. Your operations are your operations.

Performance Evaluation…

Now, this is where it gets clever. We take what we’ve planned and what we hoped to achieve and we compare it to the exceptional operational systems we have been using for ever. We need to be honest with ourselves. Again, I am not just talking about the quality of the actual unit being made or the individual service being delivered. Did we perform as expected? If we did and we are happy with the results…Score. Are there any areas where we didn’t quite hit the mark? Remember this performance evaluation is yours. You are only kidding yourself if you choose to ignore sub-par performance. I had a client once, who shall obviously remain nameless, where the Production Manager had been allowed to set his efficiency target at 90 percent. Now, there is nothing wrong with this, however; for the previous five years, he averaged 95 percent consistently. Pretty much guaranteeing his annual bonus. As a business, what would you do?

Improvement…

We all want it, we all need it and if we are not moving forward in this day and age, we are effectively going backwards. Identifying where we can get better is a good thing, in business and in our personal lives. Again though, we must work within the system. It’s pointless setting targets that are not achievable, it will only depress you. Gradual improvement is sustainable improvement. The exception to that is when we can see where a huge improvement can be made and we have the drive and resources (read – Money) to do just that.

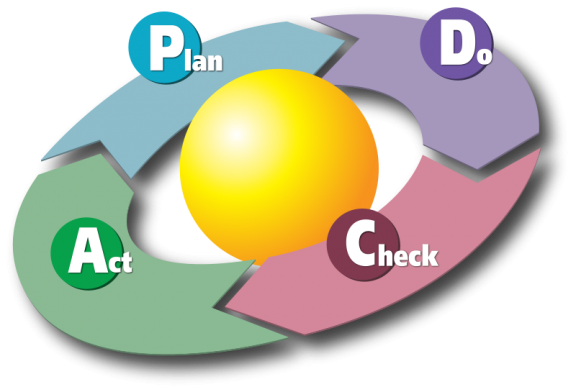

Plan-Do-Check-Act

The last five sections discussed above can be summed up in what is lovingly referred to as the PDCA cycle. It’s not new, but it is frequently skipped over when it comes to real life.

All this is done within the context of the organization and with the support from all levels of the company.

Quality Management Principles

It is interesting to note that in the opening sections of the standard (the ones I told you to ignore earlier), there is mention of the Quality Management Principles (QMP). Now these are not new. They’ve been around a long, long time and they look something like this…

Now, do any of these ring a bell? They should. Each one of these is in some way either covered by the elements we discussed earlier or buried in a shallow grave within the body of the actual standard. Each one is recognised for its importance with regards to building a robust Quality Management System. None of these can be ignored by a business that hopes to continue and grow.

In Summary…

Applying the principles of ISO 9001:2015, either in part or in full, actually makes sense. There are some exceptional tools in that rucksack we call a standard.

Applying these principles does not mean we must go for certification. Hell, my father drove a car for over forty years without a full licence. Illegal? Absolutely, but did it stop us going on holiday to Berwick-Upon-Tweed? No, it did not.

Recognising the value of the Quality Management Principles and ISO 9001:2015 is a massive step towards a sustainable future for your business. How you apply them and to what extent, is your decision.

For more information, get in touch.